Cross-section Microscopy Analysis of Interior and Exterior Paints: Thomas Everard Kitchen (Block 29, Building 9), Williamsburg, VirginiaCross-section Microscopy Analysis Report: Thomas Everard Kitchen (Block 29, Building 9, Lots 165 & 166)

Colonial Williamsburg Foundation Library Research Report Series - 1754

Colonial Williamsburg Foundation Library

Williamsburg, Virginia

2012

CROSS-SECTION MICROSCOPY ANALYSIS REPORT

Thomas Everard Kitchen

Block 29, Building 9, Lots 165 & 166

COLONIAL WILLIAMSBURG FOUNDATION

WILLIAMSBURG, VIRGINIA

May 25, 2012

Cross-section Microscopy Report: Thomas Everard Kitchen

Thomas Everard Kitchen [history.org]

Thomas Everard Kitchen [history.org]

Structure: Thomas Everard Kitchen, block 29, building 9

Requested by: Edward Chappell

Roberts Director of Architectural and

Archaeological Research

Colonial Williamsburg Foundation

Analyzed by: Kirsten Travers

Paint Analyst, Colonial Williamsburg Foundation

Consulted: Susan L. Buck, PhD., Conservator and Paint Analyst, Williamsburg, Virginia; and Jeff Klee, CWF Architectural Historian

Date submitted: May 25, 2012

Purpose:

The goal of this project was to use cross-section microscopy techniques to examine and characterize the dark brown coating discovered on the original soffit and wall plate on the west elevation (south end of the building) on the Thomas Everard Kitchen, that were exposed by Ray Cannetti, mason, on May 11, 2012. Samples were also taken from the weatherboard partition in the attic, where early exterior finishes might have been captured by the late eighteenth-century addition.

History:1

The Everard kitchen is the only surviving eighteenth-century brick kitchen in Williamsburg. It was originally constructed as a one-story, one-room, frame building sometime after 1730. At that time, the building was faced with clapboards. Around 1756 the kitchen was seemingly converted to a brick building with one frame end (the north wall). A brick extension to the north end was added in the last half of the eighteenth century, enlarging the kitchen to its present size. In the attic, the north frame wall was retained as an interior partition, protecting the early siding. This work is believed to date to the period of the Thomas Everard occupancy (c.1756-1781). The house was restored by the Colonial Williamsburg Foundation from 1949-1952.

Previous Research:

In 2006, Natasha Loeblich analyzed coatings from the captured north attic gable of the Thomas Everard Kitchen. In almost all samples, thick grime layers were found on the wood. Above this grime, some limewash remnants were observed. The presence of limewash (CaCo3) was confirmed through microchemical testing for carbonates (1M hydrochloric acid).

Procedures:

On May 11, 2012, eight paint samples were removed from the Thomas Everard Kitchen by Kirsten Travers, who was accompanied on-site by Jeff Klee (Architectural Historian), and Matt Webster (Director, Historic Architectural Resources). On site, a monocular 30x microscope was used to examine the painted surfaces to determine the most appropriate areas for sampling. A microscalpel was used to remove the samples, and sampling locations were recorded and photographed. Samples were labeled and stored in small, individual Ziploc bags for transport. All samples were given the prefix "EVK", and numbered according to the order in which they were collected (EVK 1 — EVK 8). A complete list of sample locations and photographs can be found in Appendix A.

Preliminary observations:

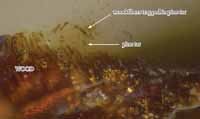

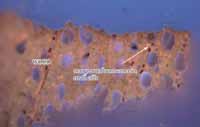

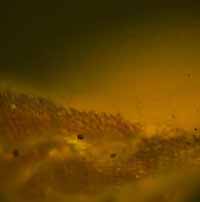

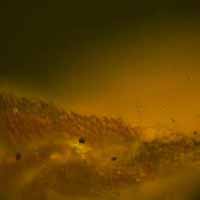

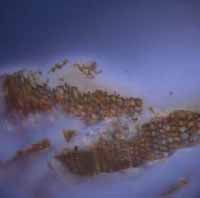

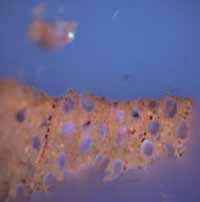

Fragments of brown resinous material from Everard Kitchen soffit (sample EVK 1). Visible light, 40x

Fragments of brown resinous material from Everard Kitchen soffit (sample EVK 1). Visible light, 40x

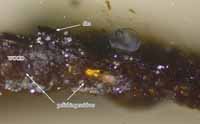

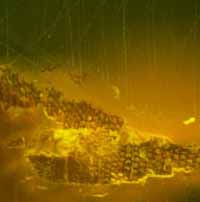

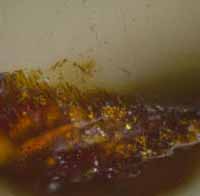

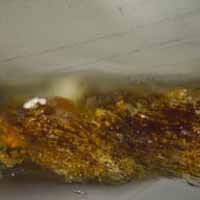

Fragments of tar from the John Blair House weatherboard (JBW 2). Visible light, 40x.

Fragments of tar from the John Blair House weatherboard (JBW 2). Visible light, 40x.

Examination of uncast sample portions with a stereomicroscope (30x) found that the coating on the soffit was covered with a thin layer of dust and other particulate matter. However, in some areas a glossy, transparent reddish material was seen just below the dust on the surface of the wood and in the wood fibers. Larger reddish-brown chunks of this material were also scattered among the sample fragments. These fragments exhibited the conchoidal fracture typical for brittle materials, such as a resin. This material was identical to the pine tar on the Blair house examined by Catherine Matsen in 2002 (confirmed via FTIR and GC-MS) and again by Kirsten Travers in 2010 (see photos above for comparison).

A small portion of this material was placed on a glass slide and heated on a hot plate. The material melted slightly and smelled strongly of pine tar.

Portions have been set aside for future analysis (such as FTIR, or GC-MS), if requested.

Results:

This investigation found what appears to be one layer of unpigmented pine tar on the surface of the soffit. No tar or other finishes were found on the wall plate or on the captured attic weatherboards. However, the boards in the attic contained so much dirt that it could obscure early tar coatings.

The results on the following pages are organized according to architectural element — the soffit and wall plate are discussed first, followed by the attic weatherboards. Paint stratigraphies have been annotated according to finish generation, and other important characteristics were also labeled. The analytical results and pertinent observations are discussed adjacent to the photomicrographs. Since many samples contained redundant evidence, only the most relevant cross-section photomicrographs are presented in this report. The results are interpreted in the conclusion.

Sample: EVK 1

Description: Soffit, adjacent to wall plate, 24" from south end

Discussion:

Samples from the underside of the soffit were all taken from an area that was captured and protected by a layer of brick wall which cased the original frame. The surface coating extends fully from the present exposed and painted area to the edge of the soffit at the wall plate.

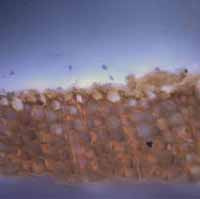

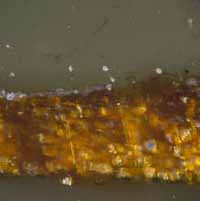

The cross-section shows one tannish, translucent layer on top of the wood. This layer has a dim, 'milkyblue' autofluorescence in reflected UV light. These characteristics were also observed in the Blair House pine tar sample (Travers 2010: 6-7). The surface of the wood appears rough, and there are wood fibers stuck on the surface of the tar, suggesting the surface was already worn (or at least very rough) when the tar was applied.

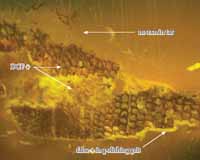

Fluorochrome stains did not detect any lipids (oils), proteins, or carbohydrates in the tar. Some positive reactions for oils with DCF were observed in the wood substrate and in the polishing grit residues. The reaction in the former could suggest that an oil was applied to the wood before the tar was applied. The reaction in the residue is most likely a false positive resulting from contamination.

There are no pigment particles visible in the cross-section. Furthermore, polarized light microscopy of a dispersed sample of the tar confirmed that there are no pigments present.

EVK 1: Soffit, adjacent to wall plate, 24" from south end

EVK 1: Fluorochrome Staining Results

DCF for lipids (oils)

EVK 1, B2A filter, 100x. Before DCF stain.

EVK 1, B2A filter, 100x. Before DCF stain.

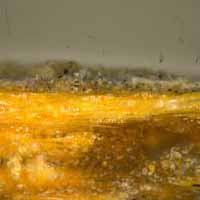

EVK 1, B2A filter, 100x. DCF reaction (bright yellow-green fluorescence).

EVK 1, B2A filter, 100x. DCF reaction (bright yellow-green fluorescence).

FITC for proteins (sample repolished)

EVK 1, B2A filter, 100x. Before FITC stain.

EVK 1, B2A filter, 100x. Before FITC stain.

EVK 1, B2A filter, 100x. FITC reaction (bright yellow-green fluorescence).

EVK 1, B2A filter, 100x. FITC reaction (bright yellow-green fluorescence).

Sample: EVK 5

Description: soffit, area not captured by brick

Discussion:

This sample was taken from an area on the soffit not captured by the brick. Only modern white and off-white paints were visible on-site.

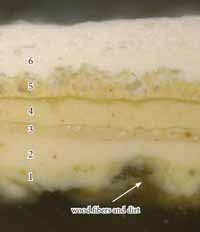

This sample cleaved at the interface of the wood substrate and subsequent coatings, and was cast as two fragments (EVK 5a and EVK 5b). The surface of the wood is very degraded, and wood fibers and dirt are embedded at the bottom of the first paint generation, suggesting this surface was already very worn when the first paint was applied. Since only six paint generations were found on this area of the soffit, all of them post-industrial (see discussion below), it seems likely that the earliest finishes wore away down to the bare wood, and no evidence of them remains.

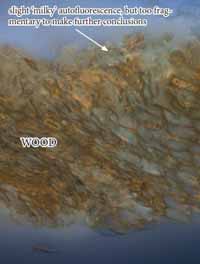

In reflected UV light, there is some material with a milky autofluorescence near the surface of the wood. This could be remnants of the early tar coating, but this evidence is too fragmentary to make further conclusions.

Approximately six paint generations were found on the soffit. All are white or off-white paints. Generations 1 and 2 have a peach-colored autofluorescence suggestive of a lead-based paint. Generations 5 and 6 have very little autofluorescence, suggestive of a synthetic (possibly latex) medium. All of these paints have finely ground pigment particles and appear industrially prepared, and do not appear to date to the 18th century.

Sample: EVK 3

Description: wall plate, underside, 21" from south end

Discussion:

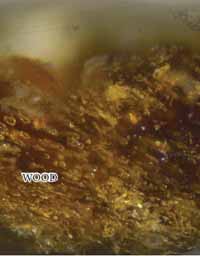

The surface of the underside of the wall plate was very dirty and no tars or other coatings were visible with the naked eye. However, a sample was collected for further examination.

The cross-section shows that the surface of the wood is very dark and grimy, but no coatings are visible. There are a few areas of orange autofluorescence in the wood cells, consistent with shellac. However, if shellac was used as a sealant, it would have been observed in the larger wood cells, as well. Since it is very unlikely that this surface was sealed with shellac (J. Klee, personal comment, May 2012), the small amount of orange autofluorescence in the wood cells is most likely a natural resin in the wood rather than a deliberate coating.

Sample: EVK 4

Description: face of wall plate, 27" from south end

Discussion:

The face of the wall plate was very dirty and no tars or other coatings were visible with the naked eye. However, a sample was collected for further examination.

In cross-section, the wood fragment appears very disrupted, but no finishes were visible.

Sample: EVK 6

Description: Attic, north room, south wall, far west end, 4th weatherboard up from bottom, 2" to right of stud

Discussion:

This sample was taken from an area that sits behind the kneewall stud in which wrought lath nails are present, suggesting it was plastered in the 18th century, possibly when the kitchen was enlarged and this room was added (c. 1770). It was theorized that this surface might have been tarred like the soffit (J. Klee, personal comment, May 11, 2012). The surface of the boards was very dirty, but no coatings were observed in-situ with the naked eye.

The resulting cross-section is obscured by polishing residues. Repeated grinding and polishing was not able to rid the sample of these residues. Interestingly, this same problem was encountered during the 2010 analysis of the Blair House tar (Travers 2010, 6), suggesting that tar might be present. However, in reflected UV light, only a thin layer of grime is visible on the surface of the wood. Instrumental analysis of the uncast sample (FTIR or GC-MS), would be able to more confidently determine if any tar is present in this sample.

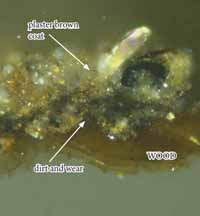

Sample: EVK 7

Description: Attic, north room, south wall, far west end, 4th weatherboard up from bottom, 2" to right of stud

Discussion:

This sample was taken from an area that appeared to have early finish captured behind the lath nailer (pointed out to K. Travers by J. Klee). It was hoped that this was the original finish on the exterior weatherboards, captured by the nailer in the late 18th century when the building was extended to the north and the room was plastered.

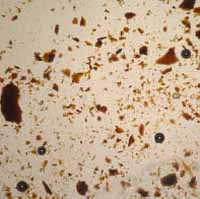

The cross-section shows that there is a great deal of accumulated dirt, soot, and particulate matter on the surface of the wood, which is very worn, making it difficult to determine if tar is present. A thick layer of what appears to be plaster brown coat is applied over the dirty wood, indicating that it was applied much later than the wood was in place. A larger chunk of this material (EVK 7a) in cross-section is seen to contain aggregates of sand and charred wood fibers in a gritty light brown matrix, which is consistent with a plaster brown coat. This might be an accidental deposit dating to when the period when the room was plastered.

This finding would suggest that either the kitchen was enlarged long before it was plastered, or, more likely, that the weatherboards are an early exterior cladding (Klee, personal comment, May 2012).

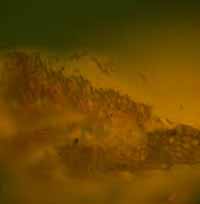

Sample: EVK 8

Description: Attic, north room, south wall, east end, 5th board up from bottom, 25" from doorway, top edge where protected by 6th board

Discussion:

This sample was taken to explore the early exterior finishes on the weatherboards in the captured gable at the north end of the attic, which was enclosed by lathe and plaster in the late 18th century.

The surface of the wood is very dirty and worn, making it difficult to determine if tar is present. The extensive soiling suggests the wood was left unpainted for a very long period of time before being coated.

Approximately eight finish generations are present. The extant coatings are brittle and appear translucent in cross-section, and are most likely unpigmented limewashes. There is not much dirt between the generations, suggesting that it was re-coated quite frequently.

Conclusions:

The wood from the soffit is coated with what appears to be a single layer of pine tar with no pigments or other organic media (oils, proteins), added. Some shellac could also be present in the wood, and fluorochrome staining suggests that lipids (oils) might also be present in the wood substrate. This would need to be confirmed with an instrumental technique such as Fourier-transform infrared spectroscopy (FTIR) or gas chromatography-mass spectrometry (GC-MS).

There was no evidence of tar on the wall plate, only evidence of accumulated dust and grime. The sample from the outer edge of the soffit (not captured by the brick) contained modern paints only. The wood substrate in this sample was so disrupted that the presence of tar could not be determined.

The captured weatherboards in the attic had extensive grime and dirt on their surfaces, so it was not clear if they were originally tarred like the soffit. Again, this could be determined by FTIR or GC-MS. A fragment of the early plaster brown coat was identified on one of the weatherboards behind the wall stud in the attic, but none of the finish plaster or later finishes were attached. The earliest coatings on the attic weatherboards appeared to be unpigmented limewashes. The first of these must have been applied well after the weatherboards were in place, due to the substantial grime layer on the wood.

For more information on tar and pitch coatings in colonial America, please see Appendix A.

Footnotes

References:

- Bristow, I. 1996. Interior House Painting Colors and Technology 1615-1840. Yale University Press.

- Buck, S., and Graham, W. Revised July 10, 2008 Unpublished typescript. Paints and Finishes in the Early Chesapeake , Robinson, N. et.al., 1987. Proof of a Pine Wood Origin for Pitch from the Tudor (Mary Rose) and Etruscan Shipwrecks: Application of Analytical Organic Chemistry in Archaeology. Analyst, vol. 112.

- Jenings, E. 1704. Re-published in the William and Mary Quarterly, series 2, vol. 3, no. 3, July 1923.

- Loeblich N. 2006. Whitewash study: Cross-Section Microscopy Paint Analysis: Brush-Everard Kitchen, Grissell-Hay House Outbuildings, George Reid House Smokehouse, Williamsburg, Virginia. Unpublished report, Colonial Williamsburg Foundation, Architectural Research Department.

- Loeblich, N. July 2007. Cross-section Microscopy Analysis of Exterior Paints: John Blair House. Unpublished report, Colonial Williamsburg Foundation, Architectural Research Department.

- Matsen, C. July 3, 2002. Analytical Report: Black Coating on Wood Sample from Concealed Cupboard, John Blair House. Unpublished report, Colonial Williamsburg Foundation, Architectural Research Department.

- Savedge, C. 1969. Brush-Everard Kitchen Architectural Report: Block 29, Building 9, Lot 165. Unpublished report, Colonial Williamsburg Foundation.

- Travers, K. 2010. Cross-Section Microscopy Analysis Report: John Blair House, Exterior Clapboard Coating. Unpublished report, Colonial Williamsburg Foundation, Architectural Research Department.

- Whiffen, M. 1984. The Eighteenth-Century Houses of Williamsburg, Revised Ed. The Colonial Williamsburg Foundation, Williamsburg, Virginia.

Appendix A. Tar and Pitch Coatings in Colonial America

Tar and pitch are some of the earliest protective coatings used to preserve woodwork in houses, public buildings, and ships since ancient times. Both materials are by-products of the destructive distillation (heating) of softwoods and birch bark. Of the two materials, tar is more viscous, while pitch is made from wood tar that has been heated further to drive off volatiles and initiate polymerization, resulting in a less viscous product (Robinson et al., 1987). Both have excellent hydrophobic properties that made them very appropriate and economical coating alternatives in the American colonies, where softwood forests were extensive. An early (1664) description of tar and pitch making in America relates that:

It [pitch] was made…from the American pitch pine…these often blew down, and when the ground was burnt annually by the Indians the bodies of the trees were consumed, leaving behind knots of timber from the point at which the boughs joined the trunk. The latter were collected and fired in a furnace made with a sloping clay floor that had an outlet for the tar. The knots were piled on this…and covered with clay. During firing, the air supply was carefully regulated, and the tar ran out the bottom…From the tar, pitch could be made 'by boiling it to a specific height(Bristow 1996).

An interesting record of pitch and tar production in colonial Virginia was written by E. Jenings on April 5, 1704 in a report for the Royal Commissioners in Great Britain:

I believe there is Annually made in Virginia near 3,000 barrells of Tarr in Princess Ann County wch containes…50,000 Acres of low Pine Land, not Agreable for tobacco…What Tarr now made, is of the Knotts & Pieces of fallen Trees….Tarr is generally sold from ten to twelve Shillings, Pitch double that rate per barrel for Goods, sometimes Money…Some is made use of by the Inhabitants for their houses Boats &c. Part disposed of to the Masters of Ships for their Use, And part Transported to Barbadoes, Jamaica & Seward Islands(Jenings, re-published 1923).

Recent research into the use of tars and pitches in the Chesapeake has been carried out by Susan Buck (conservator and architectural paint analyst), and Willie Graham (architectural historian, Colonial Williamsburg Foundation). Buck and Graham suggest that tar was of paramount importance to preserving the architecture of the region from "water-leaks and rot that so plagued the common wooden architecture of the region" (Buck and Graham, 2008). They note that not only private houses, but public buildings also received this preservative treatment, citing a number of public records, including one for Petsworth Parish which in 1680 purportedly traded four-hundred pounds of tobacco to have their church tarred that year.

Tar was not always used alone, but could be mixed with pigments and/or oils to enhance its working properties and enliven surfaces with a slight color. One such example can be found in an a written agreement relating to the painting of the St. George Tucker house in Williamsburg, dated August 30, 1798:

The top of the Kitchen, and of the shed leading down from the Cellar to the Kitchen yard, are to be painted with Spanish brown, mixed with Tar, & fish oil, & well boiled together(Whiffen, 1984).

Clearly, tars and pitches played an important part in preserving the built heritage of early America. However, these coatings are underappreciated within the greater topic of traditional paints, which often focus on decorative, rather than functional, surfaces. Continued research is warranted to further explore the extent of their use, analysis, and conservation.

Appendix B. Sample Memorandum

Cc: Susan Buck

From: Kirsten Travers

Date: May 12, 2012

Re: Everard Kitchen Paint Samples

On May 11, 2012, I collected eight paint samples (EVK 1-8) from the Everard Kitchen exposed soffit and wall plate (exterior), and some woodwork in the attic. I was accompanied on site by Jeff Klee who directed sample collection.

| EVK 1: soffit, 24" from south end (coated with black, 'alligatored' coating that appeared to be tar) |

| EVK 2: soffit, 18" from south end |

| EVK 3: wall plate, underside, 21" from south end (dirty, no coating visible) |

| EVK 4: wall plate, face, 27" from south end (dirty, no coating visible) |

| EVK 5: soffit, 12" from south end, uncaptured area past brick (only a few modern white paints seen) |

| EVK 6: South wall, far west end, 4th weatherboard up from bottom, 2" to right of stud (this area would have been captured when this room was plastered. Only dirt seen with the naked eye) |

| EVK 7: South wall, east end, 9th board up from bottom where protected by stud. Possible early finishes captured behind stud, pointed out by JK. |

| EVK 8: South wall, east end, 5th board up from bottom, 25" from doorway, top edge where protected by 6th board (take for comparison to EVK 7) |

Appendix C. Procedures

Sample Preparation:

The samples were cast in mini-cubes of Extec Polyester Clear Resin (methyl methacrylate monomer), polymerized with the recommended amount of methyl ethyl ketone peroxide catalyst. The resin was allowed to cure for 24 hours under ambient light. After cure, the individual cubes were removed from the casting tray and sanded down using a rotary sander with grits ranging from 200 — 600 to expose the cross-section surface. The samples were then dry polished with silica-embedded Micro-mesh Inc. cloths with grits ranging from 1500 to 12,000, lending the final cross-section surface a glassy-smooth finish.

Microscopy and Documentation:

The cross-section samples were examined using a Nikon Eclipse 80i microscope equipped with an EXFO X-cite 120 fluorescence illumination system fiberoptic halogen light source. Samples were examined and photographed under visible and ultraviolet light conditions (excitation 330-380 nm, barrier filter 420nm), from 100x to 400x magnifications. Digital images were captured using a Spot Flex digital camera with Spot Advance (version 4.6) software. All images were recorded as 12.6 MB tiff files and stored on a hard drive in a folder titled "Everard" on Susan Buck's laboratory computer. A separate set of images will be stored on the CWF digital database, accompanied by a digital version of the final report.

Information Provided by Visible and Ultraviolet Light Microscopy:

When examining paint cross-sections under reflected visible and ultraviolet light conditions, a number of physical characteristics can be observed to assist with the interpretation of a paint stratigraphy. These include the number and color of layers applied to a substrate, the thickness or surface texture of layers, and pigment particle size and distribution within the paint film. Relative time periods for coatings can sometimes be assigned at this stage: for instance, pre-industrial-era paints were hand ground, lending them a coarse, uneven surface texture with large pigment particles that vary in size and shape. By contrast, more "modern", industrially-prepared paints have smoother, even surfaces and machine-ground pigment particles of a consistent size and shape. Furthermore, he presence of cracks, dirt layers, or biological growth between layers can indicate presentation surfaces and/or coatings that were left exposed for an extended period of time.

Under UV light conditions, the presence and type of autofluorescence colors can distinguish sealants, clear coatings, and binding media, from darker dirt or paint layers within the stratigraphy. For instance, shellacs exhibit a distinct orange-colored autofluorescence, while natural resins (such as dammar and mastic), typically fluoresce a bright white color. Oil media tends to quench autofluorescence, while most modern, synthetic paint formulations (such as latex) exhibit no fluorescence at all. Some pigments, such as verdigris, madder, and zinc white, have distinct fluorescence characteristics, as well. UV light microscopy is critical to help distinguish otherwise identical layers often found in architectural samples- such as successive varnishes, or multiple layers of unpigmented (white) limewash.

Binding Media Analysis using Fluorochrome staining:

Fluorochrome stains adapted from the biological sciences were used to characterize the paint binding media (oils, proteins, carbohydrates), in layers within the cross-section sample. The following stains were used in this analysis:

2,7 Dichlorofluorescein (DCF): 0.2% w/v in ethanol. Fluorescent labeling reagent for lipids, particularly drying oils. One drop of stain was applied to the surface of the sample, blotted immediately, and coverslipped with mineral spirits. The reaction was observed with the B2A filter cube (EX 450-490nm, BA 520nm). This stain exhibits a yellow-green fluorescence where lipids are present.

Triphenyl tetrazolium chloride (TTC): 1.0% w/v in ethanol. Labeling reagent for carbohydrates (gums, starches, cellulosic thickeners). One drop of stain was applied to the surface of the sample, blotted dry, and allowed to sit for approximately 45 seconds before cover-slipping, (must be allowed to react with atmospheric moisture for reaction to move forward). The reaction is observed under reflected UV light conditions (EX 330-380nm, BA 420nm). A dark red-brown color is seen where carbohydrates are present.

Fluorescein isothiocyanate (FITC): 0.02% w/v in anhydrous acetone. Fluorescent labeling reagent for proteins. One drop of stain was applied to the surface of the sample, blotted immediately, and coverslipped with mineral spirits. The reaction was observed using the B-2A filter cube (EX 450-490nm, BA 520nm). A positive reaction is a bright yellow-green fluorescence.

Pigment Identification with Polarized Light Microscopy:

To collect a pigment sample for polarized light microscopy (PLM), a surgical scalpel was used to collect a small scraping from a clean, representative area of paint. The blade was then pressed and pulled across a clean glass microscope slide, dispersing the pigment particles across the surface. The pigments were then permanently embedded under a cover slip using Cargille Meltmount (refractive index 1.66). The embedded pigments were then examined in cross and plane-polarized transmitted light with the Nikon Eclipse 80i microscope at 1000x magnification (using an oil immersion objective). The observed morphologies (size, shape, agglomeration, cleavage patterns), and optical properties (including color, refractive index, extinction), were compared to reference standards as well as literature sources before making final determinations.

Appendix D. Field Notes

Cc: Edward A. Chappell

Willie Graham

Carl Lounsbury

Matt Webster

From: Jeffrey E. Klee

Subject: Everard kitchen investigations

Block 29, Building 9

Date: May 11, 2012

Yesterday, Ray Canetti removed two areas of brickwork on the west wall of the Thomas Everard kitchen to repair masonry that had been rebuilt in the 1940s and 1950s using modern, Portland-cementbased mortars. One of these was just north of the seam between the brick addition and the brick casing the original frame kitchen. The other was at the southwest corner of the building, near the wall plate. Both exposed elements of the c. 1730 kitchen frame and offer significant new information about that early building.

The hole to the north of the seam revealed, to our surprise, a 7 ½" wide corner post. Its depth is not apparent. The southern edge of the post is ½" from the edge of the seam between the masonry casing the original kitchen and the northern addition (see photograph 2012JEK0511026). Because it sits entirely north of the seam, this post would appear to be related to the addition but it is, instead, the original northwest corner post for the first period frame kitchen. The northwest corner of this post sits 19'11" north of the original southwest corner of the southwest post, which was removed during the installation of the brick casing.

This post preserves important evidence about the exterior finish of the kitchen while it was a frame building. In the area Ray exposed, there is a series of 10 nail holes in five clear clusters. Three of these holes still have iron shanks in them. The clusters are irregularly spaced: from top to bottom, they are 3 ½", 4 ¼", 5 ½", and 3 3/8" apart, or 4 1/8", on average. This pattern is entirely consistent with riven clapboard siding with a 4" exposure. No nails fall close to the 6" centers we would expect to see if it was sided in sawn weatherboards.

The hole at the southern end of the wall exposed a roughly two-foot long section of wall plate, some original soffit, the remains of a mortise for the southwest corner post, and a lap joint for an original stud, revealing important information about the frame of the early kitchen and providing some clues about interior finish.

The soffit is the original element from the frame building, as it is captured by about 6" of masonry that encases the early frame. It is secured to the underside of the joist ends with a pair of nails at each joist and is coated with at least one generation of tar. Kirsten Travers sampled the coating on the underside of the soffit that was captured by the later brick for analysis. The soffit and the finish abut the outside face of the wall plate. There is no finish evident on outside face of the plate, whose bottom edge sits 2 ¾" below 29 the underside of the soffit; nor are there any nail holes in this surface. It was likely covered, therefore, by the top clapboard, which must have been secured along its lower, thicker edge at each stud but not nailed at the top, into the plate. Both the soffit and the wall plate have been cut back, in place, at their southern end, evidently to run brick up to the underside of the end rafters. The soffit is complete, fortunately, for its outermost 4 ¼".

Enough of the plate remains to reveal much of the original mortise for the corner post. The northern edge of this mortise sits 7 ½" inches from the surviving southern edge of the soffit, suggesting a post the same width as the surviving north-west corner post. The mortise sits 1 ½" from the outside face of the plate, is 1 ¾" thick and 4 ¼" deep. The width of the hewn-and-pit-sawn wall plate is 5 ½" and it is 6 ½" deep. The bevel-lap for a stud is centered at 1'11 ½" from the southern edge of the soffit. This lap is 3" wide and about 3" high — its top edge is obscured behind the soffit. There is a single rose-headed wrought nail still in place, holding a fragment of a stud.

There is no finish of any kind visible on the lower face of the wall plate, nor is there any soot, suggesting that this surface was not exposed inside the building. A plastered interior would be entirely consistent with the wrought lath nails found in place in the attic on kneewall studs and in the underside of rafters.

The exposure of the soffit and wall plate prompted me for the first time to look closely at the eaves, which are framed in a very unusual manner. The eaves are sealed with a soffit board, but no fascia, an expedient combination which makes the building weathertight while minimizing the amount of exterior trim. This is achieved by cutting the joists back along the diagonal line of the rafters so that they taper to a point on their underside. This treatment pushes the false plate away from the edge of the joists and aligns it, instead, with the edge of the wall plate. It dispenses with the need for a fascia while protecting the end grain of the joist ends.

J.E.K.